January 03rd

Best practices for selecting case packing equipment

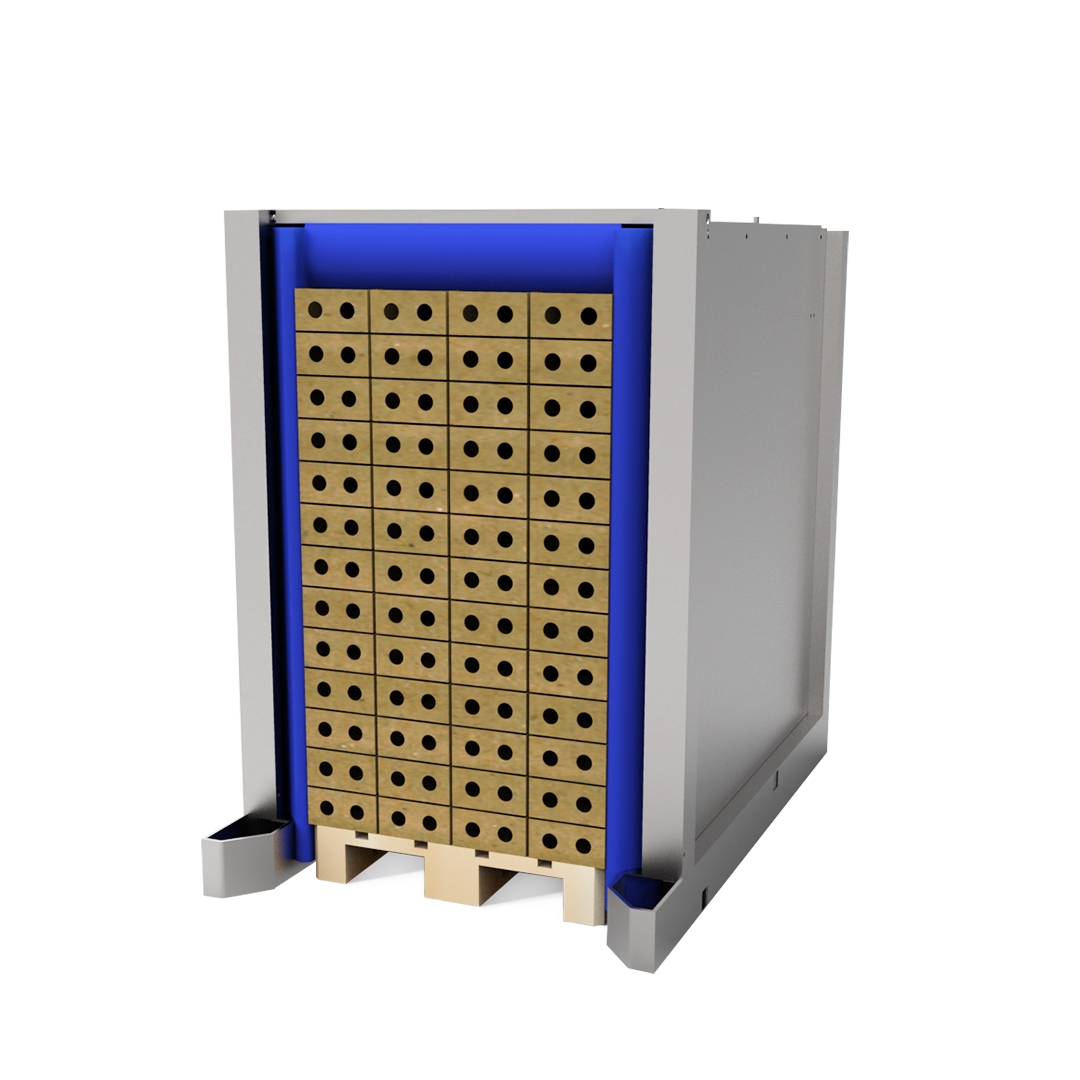

Finding the right case packing equipment for your warehouse or production line is critical to running an efficient operation. With the number of options on the market, it can be difficult to choose which machine is best suited for your application. There are certain considerations you need to keep in mind when selecting packaging equipment, and this blog post will walk you through them in detail so that you can make an informed decision about what type of case packing equipment is right for your business. Read on to learn more about the best practices for selecting case packing equipment !

Here at Enoline Solutions, with our 30+ years of experience as packaging line integrators, we help you find the perfect packaging solution your business needs !

1 - Know Your Product Loading Orientation

When selecting case packing equipment, one of the best practices is to know your product loading orientation. Do you need a top, side, or end-loading configuration? Asking yourself this in advance can help you narrow down the types of vendors and equipment you should be considering, saving time and energy. Another best practice is to ensure that your design includes reliability - can the loading orientation be changed to enhance reliability? Answering these questions upfront will lead to better-selecting decisions in the long run.

2 - Look Into How The Case Packer Is Reacts To Variances In Materials

Besides knowing the product loading orientation, you also need to consider how the case packing equipment will react to different materials. Are there any variances in material weight or size that could affect the performance of your machine? If so, what are they, and how can they be addressed? Taking a closer look into this aspect of your selection process is key to ensuring that your case packing equipment runs smoothly and efficiently.

3 - Evaluate Different Options For Automation

No matter the size of your operation, automation is likely to be a factor when selecting case-packing equipment. Consider what level of automation you want - manual loading or automated? Do you need any additional sensors or other components to help ensure accuracy and reliability? Research different options for automation to determine which best suits your needs and budget.

4 - Ask Other Users About Accessibility

If you're considering a particular case-packing machine, it's always good practice to ask other users about its accessibility. How user-friendly is it? Can anyone use it without having to go through extensive training? What type of technical support do they offer? Asking questions like these will give you greater insight into the overall usability of the equipment and help you make a smarter decision.

5 - Consider Maintenance Requirements

When selecting your case packing equipment, consider its maintenance requirements. Does it require frequent cleaning or adjustments? How easy is it to access parts and components for repairs? Knowing the answers to these questions can help you determine if the machine you're considering is the right fit for your business.

6 - Find Out What Happens When You Change Sizes

It's important to ask what happens if you need to change the size or orientation of the cases. Will you be able to do this without having to purchase entirely new equipment? How much downtime will it require? (by the way you can read our article about how to reduce downtime here) Ensure that you understand the process for making these changes before committing to a particular machine.

7 - Product Control In Case Packing Is Of Vital Importance

When selecting case packing equipment, product control is of utmost importance. Be sure to assess whether the speed and position control offered by actuators such as air cylinders meet your standards. Low-tech drives may seem sufficient initially, but evaluating whether they can keep up with constant speeds and linear velocities over time is essential. In the event that a machine jams, it's worthwhile to consider if the cause lies in outdated technology or slower acceleration that is unable to keep up with the rate of infeed. Investing in modern case packing technology that can handle larger volumes of product and provide maximum efficiency is ultimately most beneficial for your business.

8 - Consider Glue Versus Tape

Finally, you should consider whether the case packing equipment should use glue or tape to seal the cases. Both have advantages and disadvantages - for example, the tape is often cheaper but more prone to errors. Glue provides better product protection and a tighter seal, but it can be more expensive. Consider all these factors in your decision-making process.

Conclusion

By following these steps, you can help ensure that you purchase the right case packing equipment for your business. Taking the time to research and consider all the available options will help you make an informed decision that will pay off in the long run.

We are here to help you find the perfect packaging solution your need, contact us for a fast and free quotation