VARIETY PACKS MADE EASY WITH ENOLINE SIDE LOADING MACHINE

Variety is believed to be the spice of life. Beer is often referred to be the "herb of life." As a result, drink variety packagings (mostly variety beer IPA packs or soda variety packs) are flying off liquor store shelves across the country. However, this isn't limited to canning and bottling for craft brewing or alcohol in general; an increasing number of beverage and food companies are looking to diversify their offerings. Certainly, multiple flavors in the same pack can appeal to a big family with diverse tastes, a group of friends, or simply someone who enjoys a little variety now and then.

To gratify the consumers, manufacturers might have to make a difficult choice as variety packaging usually involves high capital investment in infrastructure.

Variety / Assortment / multi-flavor packs do take longer to process and need more manpower, but by introducing technology to the case packer, such as unloading tables and a lane system, the production process can be simplified efficiently.

For most producers, who normally only have a single packaging line, a multi filler and case packer with different lanes for each type of product is a bit of a pipe dream.

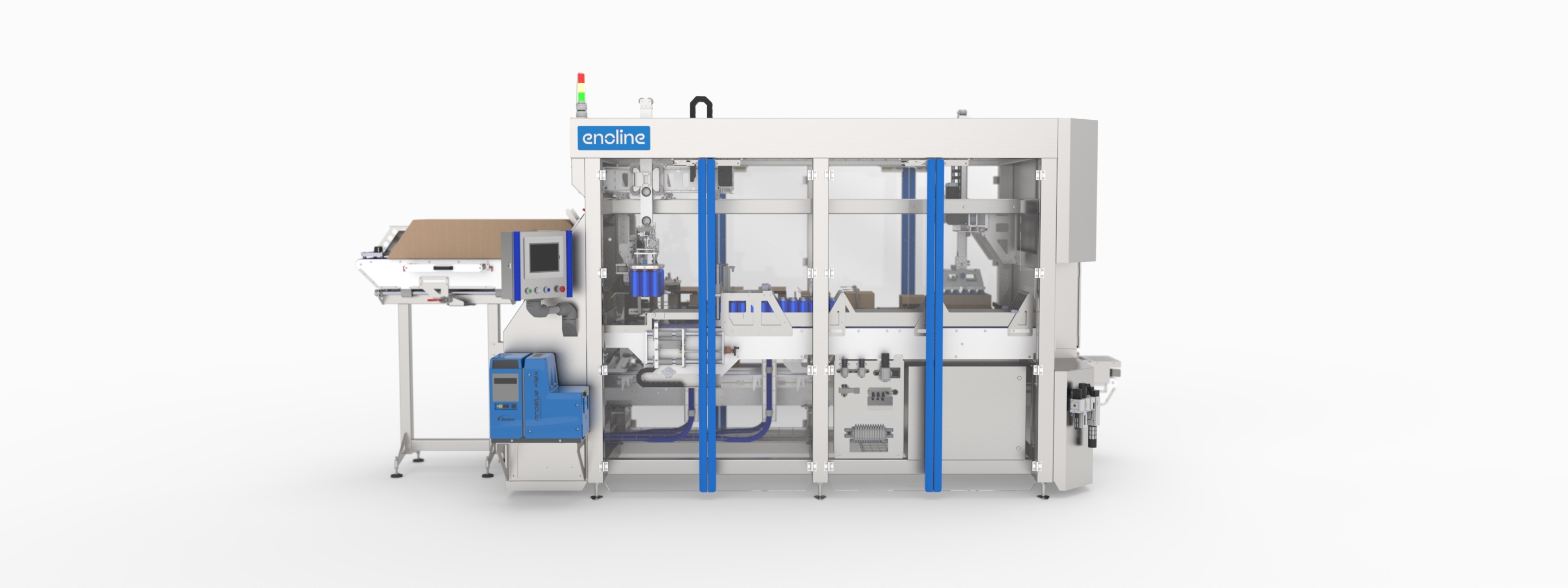

With over 40 years of expertise as primary, secondary, and tertiary packaging machine integrators, this time Enoline developped an extremely versatile and user-friendly side loading variety pack machine with packaging infeed lanes that can produce up to 20 variety packs per minute! It works with beverage cans, but also with glass bottles and tin cans. Finally, this can, tin can and bottle case packer machine is one of the most cost-effective and compact side loaders on the market.

In this post, we will look at the packing techniques you may consider in order to create a variety pack, as well as the benefits of our automated side loader system.

Would you like to automate your packaging process? You're wondering which option will best match your requirements. We're here to help you find out, so get in touch and obtain a free quote for your job!

Packing by Hand ?

The easiest and most fundamental method for packaging variety packs is to pack everything by hand. This method is labor-intensive and time-consuming, but it does not involve the addition of new equipment to the current packaging line. This type of packaging is recommended for small-scale businesses.

Consider the following scenario: you want to package a 24-piece variety pack with four different tastes. You'll need four pallets of items that correspond to the flavors you want in the pack adjacent, and you'll need six of each to fit into your current packaging lane. You must also consider your product alignment every time, and how will the items be displayed to the client when he opens the box.

One to three individuals are required to manually fill and place the variety packs, it can get very monotonous & time-consuming for the workers, thus impacting the overall numbers.

Packer Infeed Lanes Enoline Solutions

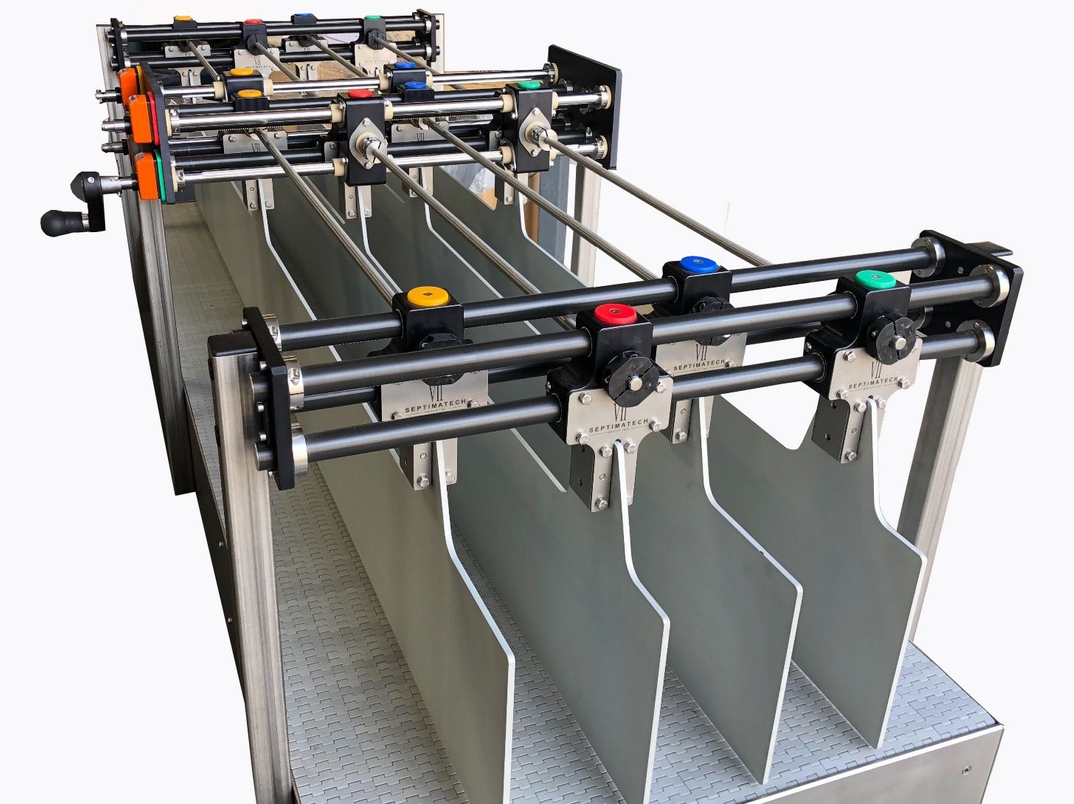

Most manufacturers use a case packer to move product cases into multiple infeed lanes. Variety packs are packaged using this technique. To feed each lane of the case packer on the manufacturing line before the case packer, hand packing tables and removable/adjustable/ adjustable lane handling systems are necessary. If there is enough space adjacent to these hand-packing tables, pallets of beer or Cola Hard-seltzer, energy drinks, cold brew coffee cans, or any other product can be brought into place more easily.

However, these solutions aren't very adaptable, and they don't link well with one another because they weren't designed to be utilized in this way in the first place. They're expensive, and they take up a lot of space, and we all know that by saving on space more comfort can be provided to the employees & additional machinery can be added in the future to boost production rates. As a result, compactness is a crucial specification.

Furthermore, every manufacturer, such as breweries, is looking for different packaging sizes. Final packs of 4, 8, 12, or 24 (the most typical) beers, wine, soda, iced tea, tin can food, and so on can be chosen. Moreover, packages can include a range of different flavors from 2 to 8 or more (variety packs / mix packs).

When possibilities are unlimited, having a flexible and easy-to-use machine is the key, and we built our automated machine around all of these factors.

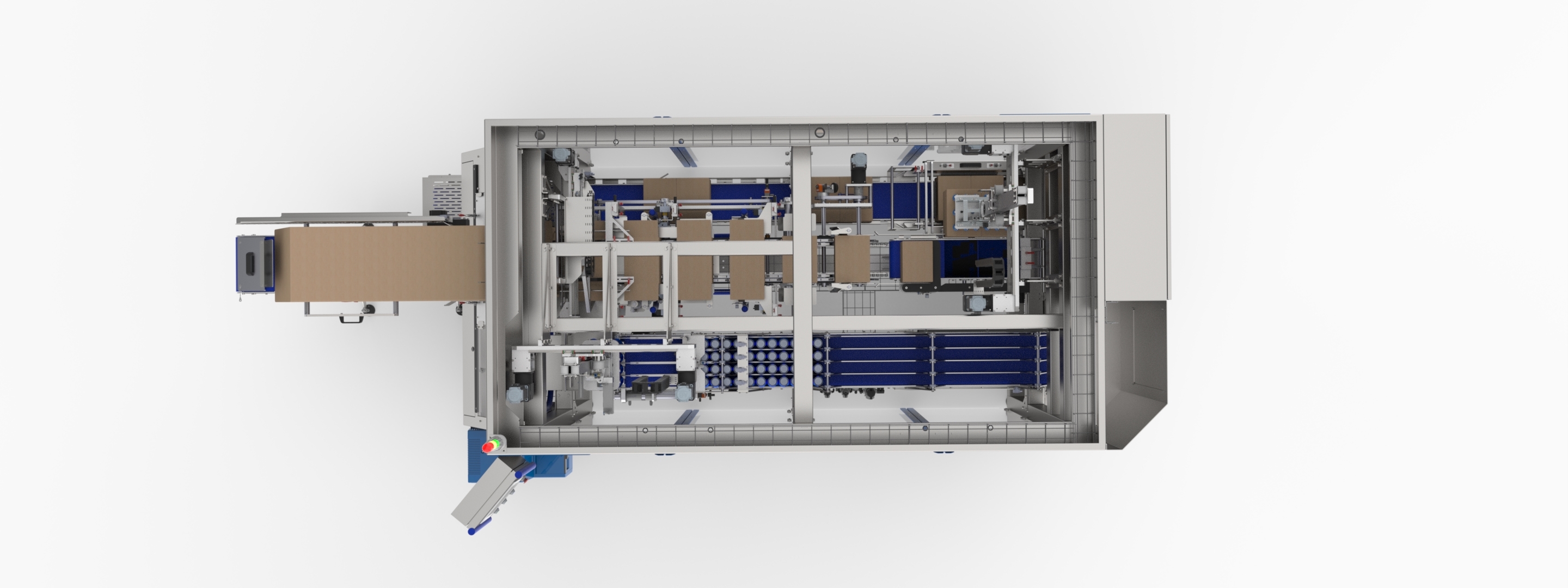

We provide our all-in-one side loading solution, which includes feeding lanes and a case packing solution that adapts to your product, as a solution to your variety packaging demands. In fact, we provide a custom packing solution that allows you to select the number of infeed lanes you require (here shown with four lanes) as well as the sort of final packaging you need.

Our Enoline side loading packing machine incorporates the number of lanes you need and is simply adjustable to various pack sizes.

A robotic arm will grab your cans, glass bottles, or tin cans and insert them sideways into the premade box before sealing it simultaneously while a cardboard blank is being formed as a carton box. Final variety packaging will be designed as specified (the most frequent are 4-6-8-12-24-packs) and will have the elements as needed (handle, reinforced bottom pack, etc.). They can also be directly placed in a double tray pack ready to be palettized, saving even more time.

Even while this last activity can be easily automated with a loading station we offer as an option, the only thing left for your operator to complete by hand (just one is required, compared to three if you do it manually) is loading cardboard blanks and items into the lane. This will take very little time and effort, and the machine will take care of the rest automatically.

To meet the needs of medium- to large-scale businesses, the production rate can reach 20 cases per minute or 1200 cases per hour.

Installation and configuration are simple, and our professional team will walk you through all you need to know after the machine is installed.

With its superb optional stainless-steel frame and well-chosen components, we put our machine through the most rigorous durability testing in order to provide you with the greatest possible product, one that is both trustworthy and robust. Thanks to mainly the local production and the great work of Enoline engineering teams, we were able to keep the price of our solution as low as possible.

We are very pleased to confirm that this is the lowest price for this solution in the market right now.

As a result, you'll have more revenue, more workspace, more productivity, and motivated staff.

See our variety pack system in action :

Loading Stations options

There's a range of loading station layouts and options available now. Although a stainless steel table is always used to unload a pallet of products, there are a number of different techniques to get the product from the stainless steel table to the conveyor system.

There are some options available.

Some producers prefer to use the stainless table to place the cans directly into the packer's infeed conveyors. Others (mostly brewers) can unload into a bi-directional stacking table if more accumulation is required in front of their case packer. As a result, the case packer can package more cans at a faster rate, resulting in less downtime.You can also get automated loading and unloading system. When the brewery isn't manufacturing variety packs, a bi-di table will be employed as an accumulation table for the packer's infeed.

Enoline can provide a complete set of bulk bottles, can depalletizers, automatic shrink wrap removers, trays, and can separators if total automation is requested.

We are here to answer all your questions, please feel free to contact us and tell us about your project, we will find the solution that meets your needs and draft a quotation free of charge!