Lassonde Inc.

Lassonde develops, produces, and markets a wide range of ready-to-drink fruit and vegetable juices and drinks. Lassonde has a long time history with Enoline. They were the first to install aseptic juice filling in 1986 with an Enoline turnkey solution that included blow molding, filling and packaging.

In a nutshell

Product handled

Plastic jug

How Enoline helped

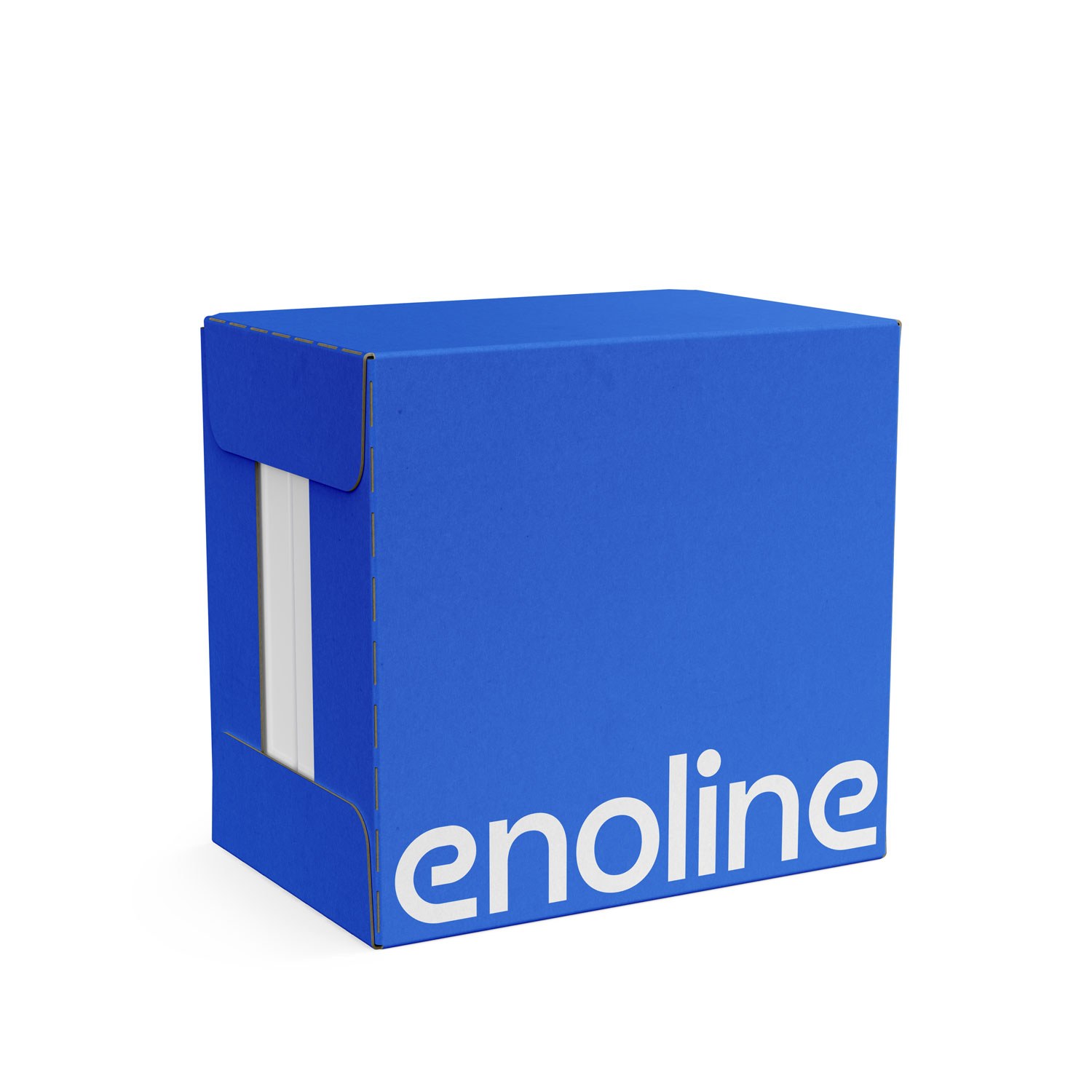

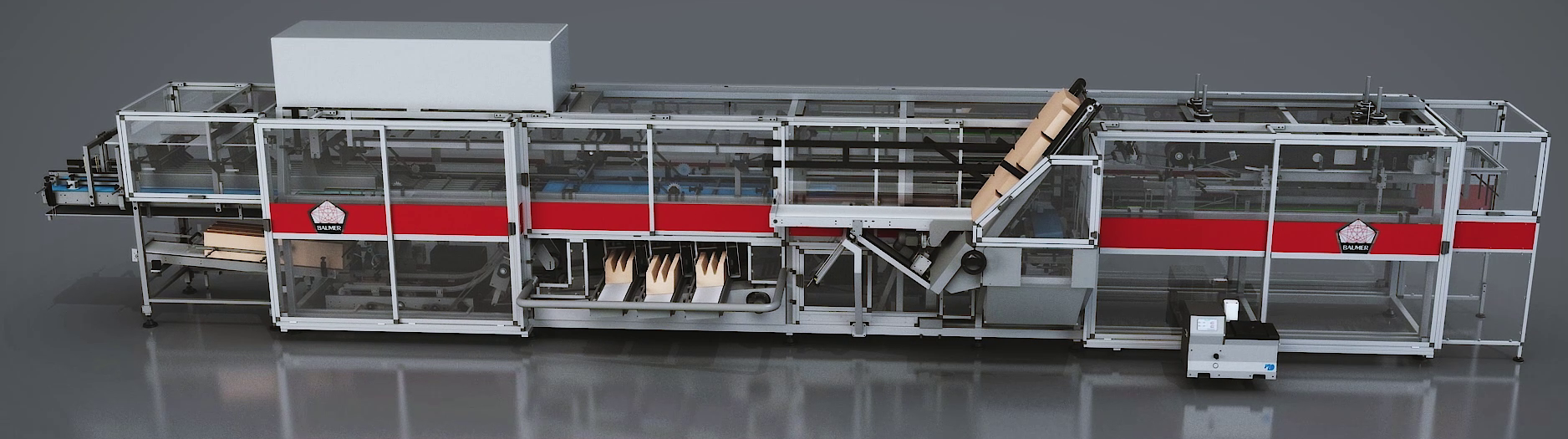

This low acid aseptic juice line is still running and Lassonde came back with a request to revamp their packaging. A Baumer wrap around case packer is now installed in the same line with high performance and enormous versatility.

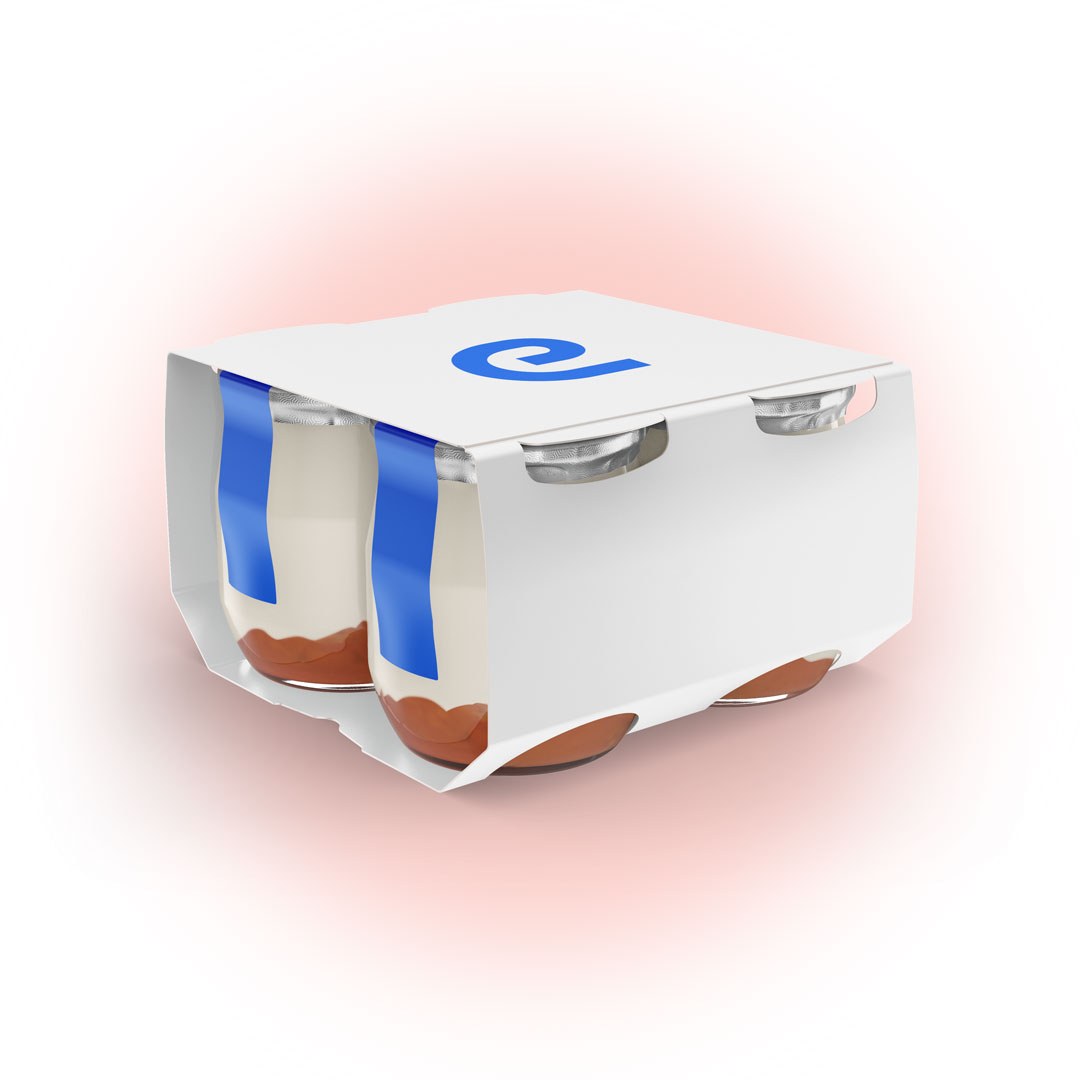

This shelf ready solution is remarkable. The packer can produce short side leading or wide side for different Retail Ready presentation.

The oval shaped bottle is hard enough to handle and we provided an independent bottle turner at the infeed to produce this variety packs.

Rectangular bottles are also part of their wide SKU variable. Over 200 different SKU’s.

Versatile packaging is realized with quick changeovers which are realized through a simple “Patented” 90 Degree infeed system. This very short infeed results in a compact solution 8,2m or 27 feet long will fit any existing plant.

“Its an example of packaging equipment where we train our operators”

Solutions that really made the difference

for Lassonde Inc.

The technology put in place

View more success stories as told by some of our dearest clients

Interested in our services?

Let's get in touch.