Upstate Niagara Cooperative

Upstate Niagara Cooperative is owned by over 300 family farms. The ever expanding Greek yogurt market has become key production in this NY State large tub private brand co-packer. Some larger cups require more than three hours of cooling. This product has to sit for long periods in order to stop maturation, stabilize the pH and product cannot be moved otherwise the surface cracks open and quality is affected.

In a nutshell

Product handled

Yogurt cup

How Enoline helped

The customer was faced with either building a large refrigerated storage area to improve cooling efficiency of his Greek style yogurt. At first the client was considering a long very long cooling tunnel

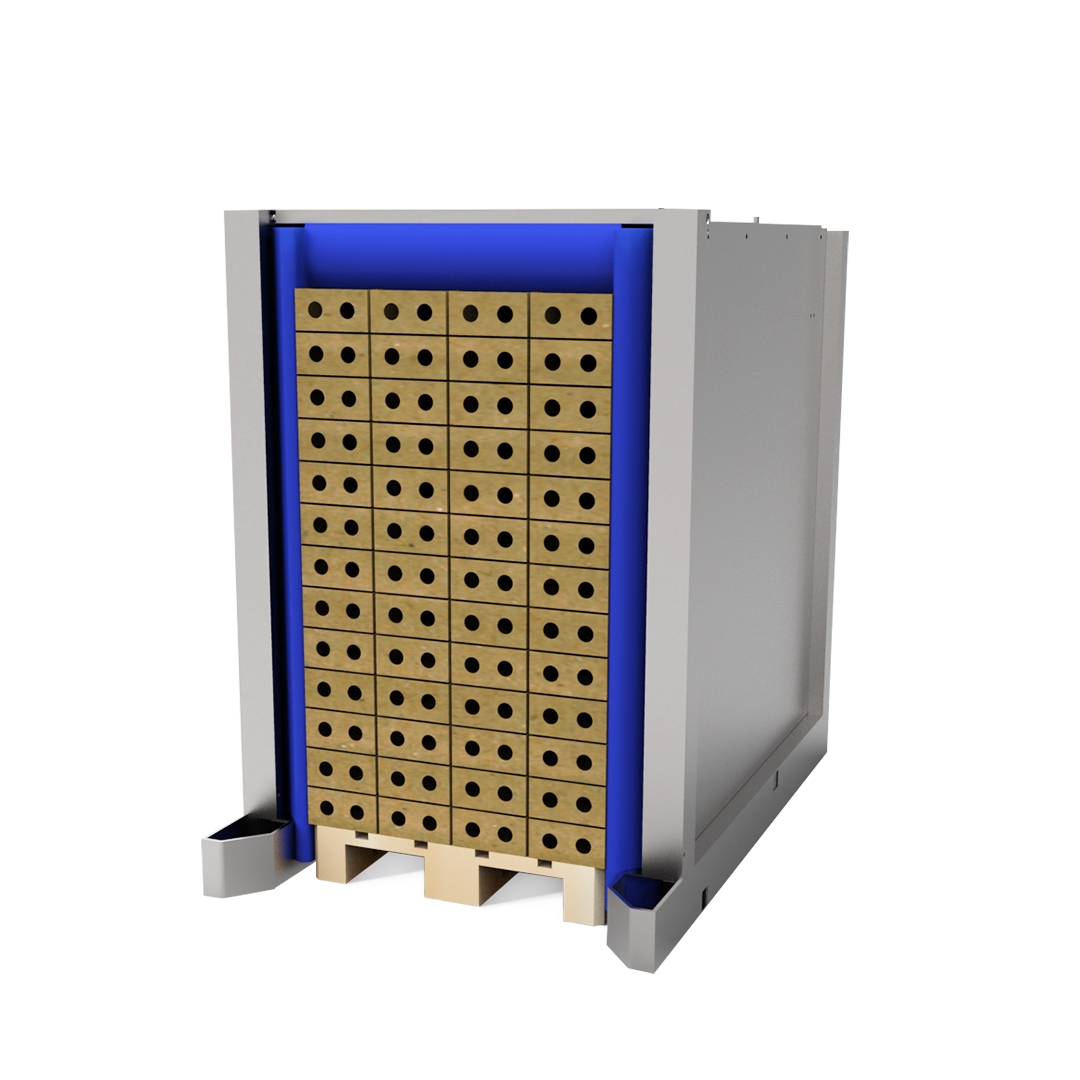

Fromfroid cooling cells were tested and demonstrated how efficiently, large tubs of palletized product could be cooled down.

The warehouse space is minimal and product can only be shipped once cooled down to less than 6°C at the core of the pallet.

With high efficiency cooling cells the client compared Fromfroid cells with better than 50% improvement over existing competitor’s cells.

With testing results the client purchased over 40 cells in an existing part of the plant two cells high. A PLC automatically controls pallet conveying, tracking product with individual cooling times.

“We originally planned for more cells but these turned out more efficient than expected”

- Corporate Engineer at Upstate Niagara

Solutions that really made the difference

for Upstate Niagara Cooperative

The technology put in place

View more success stories as told

by some of our dearest clients

Give us a call if you're interested

in this solution for your business