July 03rd

Packaging Innovations: Wrap Around with Unique Partition System for Glass Bottles, and more !

Introduction

In the competitive world of beverage packaging, staying ahead with innovative solutions is crucial. One such groundbreaking packaging innovation is the Enoline Baumer Wrap Around with a unique partition system for glass bottles.

This revolutionary packaging solution offers exceptional protection, convenience, and aesthetic appeal, making it the preferred choice for liquor, wine, beer, sodas, and a lot of products ! Let's delve into the details of this remarkable packaging system and explore its benefits for both manufacturers and consumers.

Packaging Innovations: Enoline Baumer Wrap Around

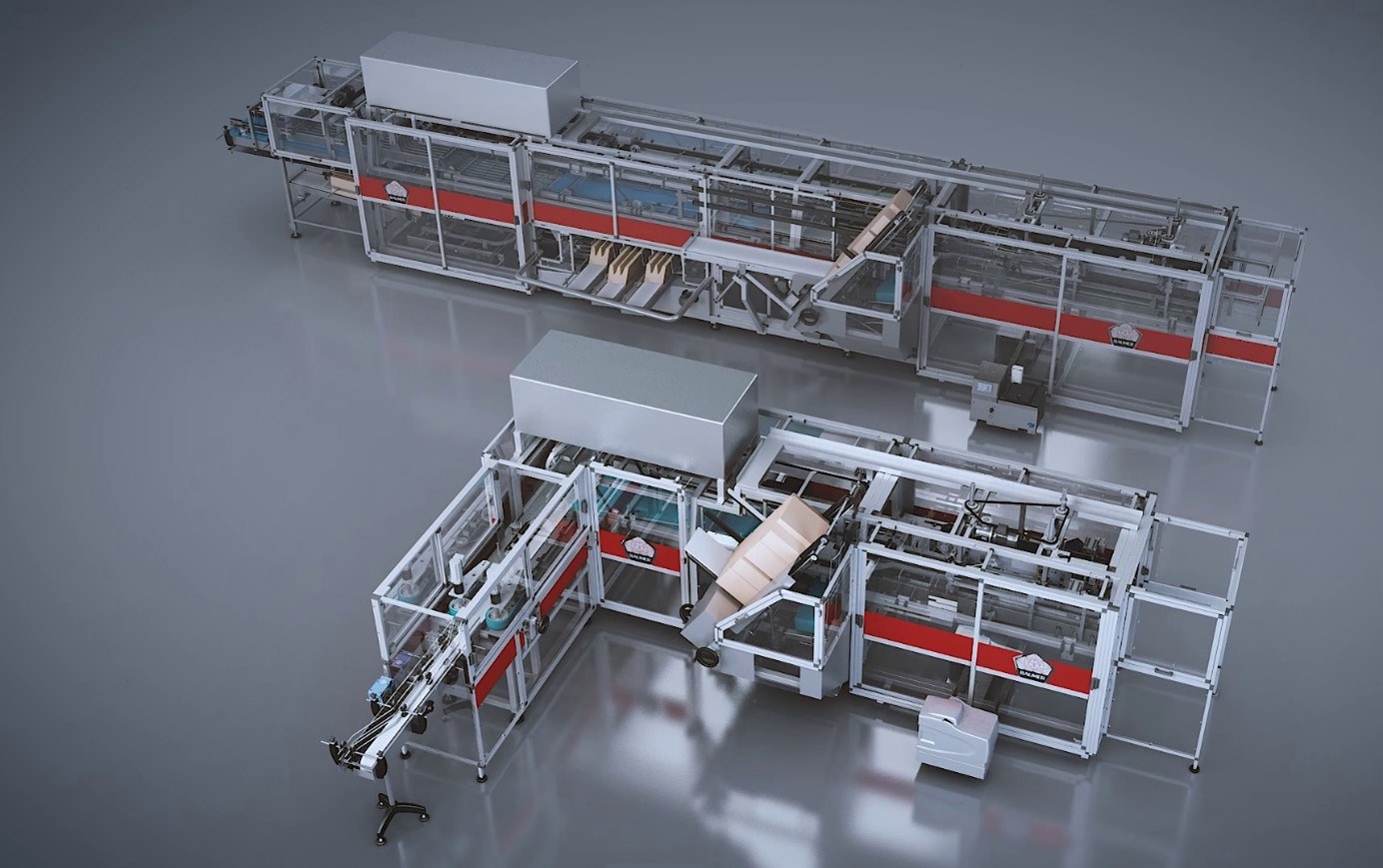

The Enoline Baumer Wrap Around packaging system is a game-changer in the beverage industry. Its unique design and partition system provide superior protection for glass bottles, minimizing the risk of breakage during transit and storage.

This packaging solution ensures that your products reach the market in pristine condition, free from any damage or leakage.

Benefits of Enoline Baumer Wrap Around

1. Enhanced Product Safety

The Enoline Baumer Wrap Around's partition system creates individual compartments for each bottle, preventing them from colliding with one another. This reduces the risk of breakage, ensuring that your products are delivered intact and safe for consumption.

2. Optimal Space Utilization

With its efficient design, the Enoline Baumer Wrap Around maximizes space utilization, allowing you to pack a higher quantity of bottles in a compact manner. This not only reduces packaging costs but also optimizes transportation efficiency by accommodating more units per shipment. This machine comes with a 90 degrees infeed option for even more warehouse space optimization.

3. Easy Handling

The wrap-around structure of this packaging system simplifies the handling process. The partition system holds the bottles securely, preventing slippage or movement during transit. This makes it easier for warehouse personnel, distributors, and retailers to handle and stock the products.

4. Visual Appeal

The Enoline Baumer Wrap Around offers an aesthetically pleasing display of your glass bottle products. The packaging can be customized with vibrant graphics, branding elements, and product information, enhancing the shelf appeal and attracting consumers' attention.

5. Sustainability

In line with the growing demand for eco-friendly solutions, the Enoline Baumer Wrap Around is designed with sustainability in mind. The packaging material is recyclable, reducing environmental impact and aligning with the principles of a circular economy.

How Does the Enoline Baumer Wrap Around Work?

The Enoline Baumer Wrap Around employs a smart partition system that ensures the bottles are securely held in place. The design consists of individual compartments that perfectly fit the shape and size of each bottle, preventing them from touching or colliding. The partition system acts as a cushion, absorbing any shocks or vibrations that may occur during transportation.

Additionally, the wrap-around structure of the packaging adds an extra layer of protection, safeguarding the bottles from external impacts. The materials used in the Enoline Baumer Wrap Around are carefully chosen to provide durability and resistance to moisture, ensuring the integrity of the packaging throughout the supply chain.

See our machine in action !

Conclusion

The Enoline Baumer Wrap Around with its unique partition system for glass bottles offers an exceptional packaging solution for liquor, wine, beer, sodas, and other glass bottle products. With its enhanced product safety, optimal space utilization, easy handling, visual appeal, and sustainability features, it is revolutionizing the way beverages are packaged and transported. By choosing the Enoline Baumer Wrap Around, manufacturers can ensure their products reach consumers in pristine condition, maintaining product quality and customer satisfaction.

Embrace the packaging innovation of Enoline Baumer Wrap Around and experience the advantages it brings to your business and the entire supply chain.

FAQs

1. Q: Can the Enoline Baumer Wrap Around accommodate bottles of various sizes?

A: Yes, the Enoline Baumer Wrap Around is highly versatile and can be customized to fit bottles of different sizes and shapes. Whether you have liquor bottles, wine bottles, beer bottles, sodas, or other glass bottle products, this packaging solution can be tailored to meet your specific requirements.

2. Q: Does the Enoline Baumer Wrap Around provide protection against temperature variations?

A: While the primary purpose of the Enoline Baumer Wrap Around is to protect bottles from physical damage, it also offers some insulation against temperature changes. The packaging materials used have thermal properties that help maintain a more stable temperature inside the compartments, safeguarding the contents to some extent.

3. Q: Is the Enoline Baumer Wrap Around cost-effective compared to other packaging options?

A: Yes, the Enoline Baumer Wrap Around offers cost savings in several ways. Its space-efficient design allows for higher packing density, reducing transportation costs. Additionally, the protective partition system minimizes the risk of bottle breakage, eliminating potential losses due to damaged products during transit.

4. Q: Can the Enoline Baumer Wrap Around be customized with branding and graphics?

A: Absolutely! The Enoline Baumer Wrap Around provides ample space for customization. You can incorporate your brand logo, product information, and eye-catching graphics on the packaging, effectively promoting your products and creating brand recognition among consumers.

5. Q: Are the materials used in the Enoline Baumer Wrap Around eco-friendly?

A: Yes, the Enoline Baumer Wrap Around is designed with sustainability in mind. The packaging materials are recyclable, contributing to a more environmentally friendly packaging solution. By choosing this option, you align your brand with eco-conscious practices, meeting the expectations of environmentally conscious consumers.

6. Q: Can the Enoline Baumer Wrap Around be used for other types of packaging apart from glass bottles?

A: While the Enoline Baumer Wrap Around is primarily designed for glass bottles, it can potentially be adapted for other packaging formats as well. Manufacturers can explore customization options to accommodate various products such as jars, vials, or other fragile containers.

Let us find the best wrap around case packing machine for your business !