Wrap around case packing VS RSC American boxes Enoline

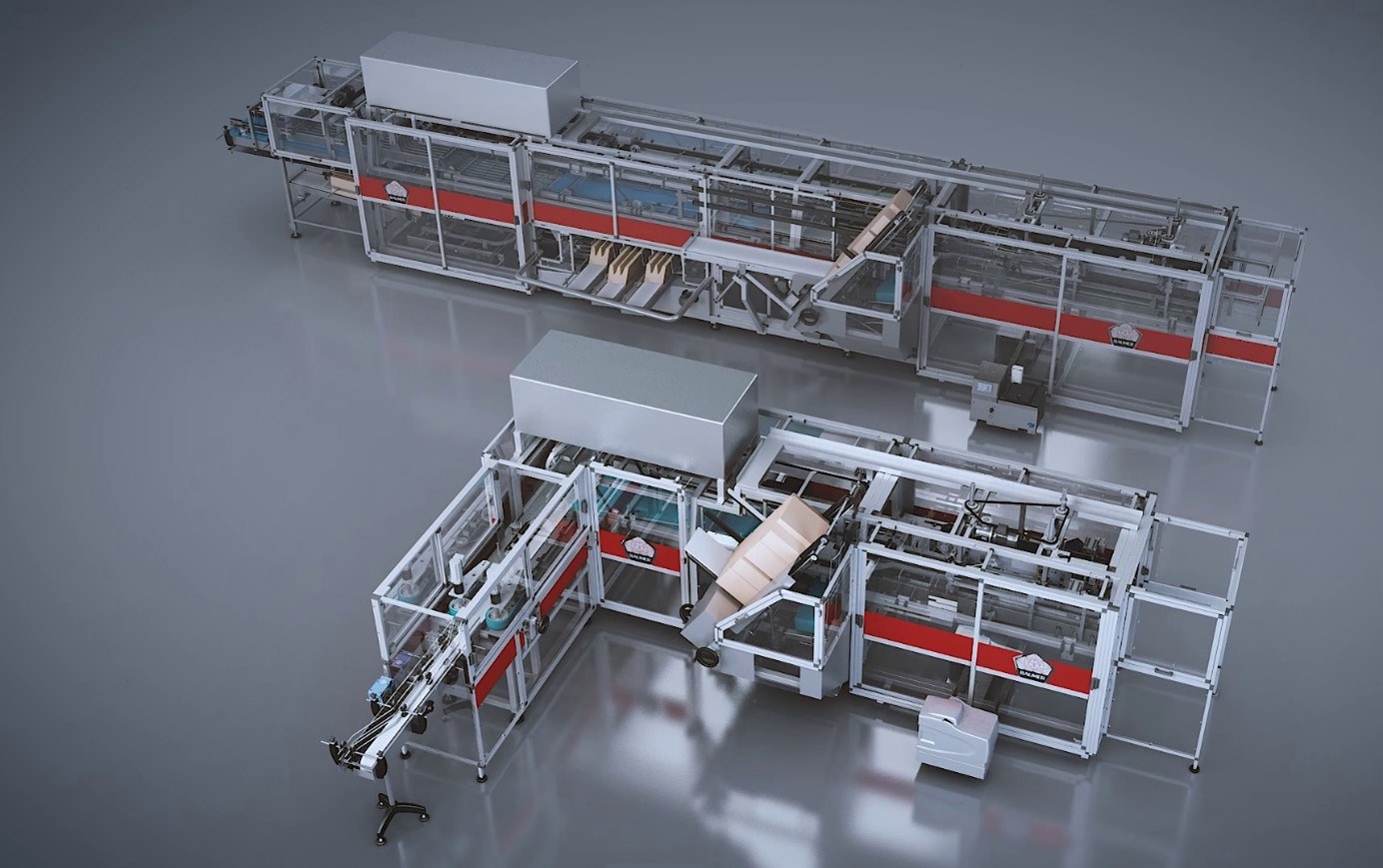

You are a company looking for the best way to pack your products, you need speed, cost effectiveness and reliability and you are looking for a compact packing machine. Baumer's Wrap-Around Case Packers allow you to pack in display cases, high trays and trays.

Advanced technology and dedicated optional systems make these machines suitable for any type of product, including geometrically complex containers (rectangular, oval, ...). The packages are wrapped around the products, which makes them strong and robust.

In this article we explain in more detail what makes these cartoning packaging machines the best on the market today if you want to automate your production in an optimal way. We will oppose wrap around case packaging to RSC box packaging to help you choose the best suitable solution for your company.

RSC box meaning / RSC carton meaning

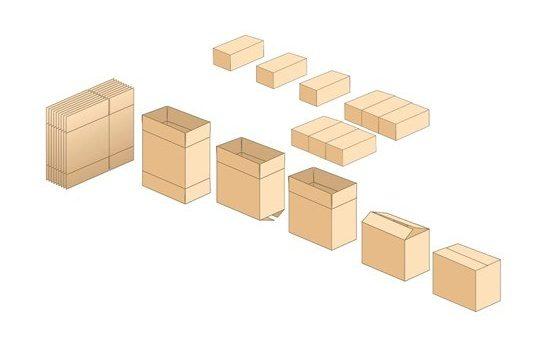

RSC stands for "Regular Slotted Case", also called "American Case". The case is shipped pre-glued, volumized on the packaging line and usually filled from the top, then sealed with tape.

RSC cardboard boxes or RSC cases or R.S.C cartons are popular because they can be easily assembled by hand from a folded state. This is because the manufacturer's flap of the case is already sealed in the right place. The side flap is pre-glued, and the case can be sealed with tape only. This solution can only be advantageous if you are doing manual or low speed case packing. The operators in charge of this task will only have 1 or 2 flaps to fold and seal the RSC box.

What is a wrap around case ?

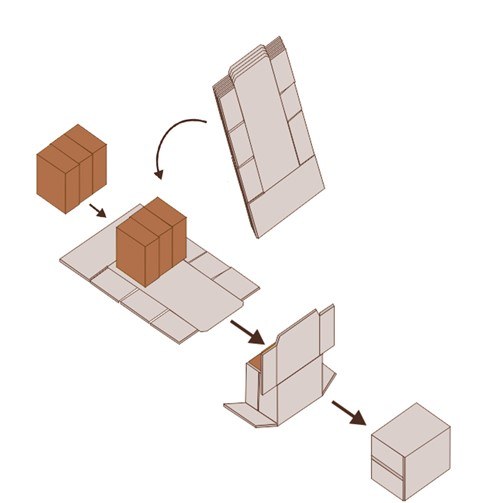

A wraparound box packaging is essentially a corrugated board blank. The blank is specific to the case packing plan. It is formed around the case by the wrap around case packer. In some wrapper packaging machine configurations, the wrap around blank is partially formed to allow the product to be loaded into it from the side. In other configurations, the product is synchronized in-line with the arrival of the blank.

The case is formed around the products. The side and top flaps are then closed and glued. This operation is usually done with automatic equipment. Although a wrap-around case looks like an RSC box when fully formed and sealed, it has unique advantages over an RSC case and it is perfect for industrial packaging.

Food, beverage, and consumer product manufacturers are always looking for ways to reduce the cost of their products and improve productivity. Material cost is always one of the most closely watched measures, including the corrugated box used to ship products to customers. Case style changes are often considered to reduce costs. Switching from an RSC design to a wraparound box packaging design is quite common as the cost savings quickly pay for this technical change. A wrap-around process can allow manufacturers to reduce costs through the benefits we outline in the rest of this article.

Main advantages of wrap around cases over RSCs

Gain in cardboard

Wrap around corrugated boxes allow a tight packaging around the product. As the blank is specifically designed to fit the dimensions of the product, the amount of cardboard used is optimized. This is not only good for the overall result with a better fitting package, but also for the environment. Additional cardboard savings can be achieved with the use of so-called economy boxes. In this case, the side flaps are not joined together. As a rule, cardboard manufacturers offer a price reduction of about 10% on wrap-around box blanks compared to RSC boxes.

RSC blanks pile

Logistical cost savings

Wrap-around case blanks take up less space than RSCs, which increases the space available on pallets for transport, for example. More blanks on a pallet means less transportation costs, it is possible to have about 20-60% more blanks on each pallet with wrap-around blanks than with RSC. On average, 10-30% of transportation costs can be saved for corrugated supply and expensive floor space in manufacturing facilities can be better utilized. Operational Benefits.

The Wraparound case packer magazine can hold approximately twice as many blanks as the magazine of an RSC case packer. The use of the wrapping packing machine means less operator intervention to replenish blanks on an automated machine. This generally means less operator time required to supervise a line.

Although there is a common perception that RSC cases have greater stacking strength when palletized, a wrap-around box can have equally great stacking strength if designed correctly.

Wraparound case packing can achieve a much higher speed than automatic RSC packing.

we talked about wrap around packaging innovation in 2024 in this article

You can also learn why our wraparound case packer is perfect for glass bottles with our patented technology

Wrap-around blanks

Conclusion

We deliver worldwide

Overall, the only advantage an RSC has over a wrap-around machinery is

that it is more efficient if your plant is operating with manual

packaging, as the cartons are already pre-formed.

However, for a company wishing to automate this wrapping packaging process to increase production volumes and productivity, it should seriously consider the wrap around packaging technology, which is much more economically and technically advantageous than RSCs.

You want to know more? We can establish with you, free of charge, which solution would suit you best.