How to choose a fast cooling solution for your food company

Various items in the foodservice industry rely on industrial cooling to establish proper food preservation.

We provide you with unique and inventive turnkey solutions that are tailored to your demands and fully integrated into your end of the line, helping you to save space, energy, and productivity, and hence gain profit.

We explain everything you need to know about increasing the speed of cold air chilling of food items with our solutions in the following paragraphs, as well as how they can benefit you in your agro-industrial business.

The context

You have a company that manufactures and sells goods that must be cooled before being distributed in the market. This primarily applies to dairy products (yogurts in jars or drinks, dairy items, etc.), fruits, vegetables, and prepared meals.

You want a simple and efficient, long-lasting, and flexible solution for the immediate cooling of a large number of items simultaneously. You want full dependability, which means little to no maintenance.

OUR PATENTED FROMFROID SOLUTIONS

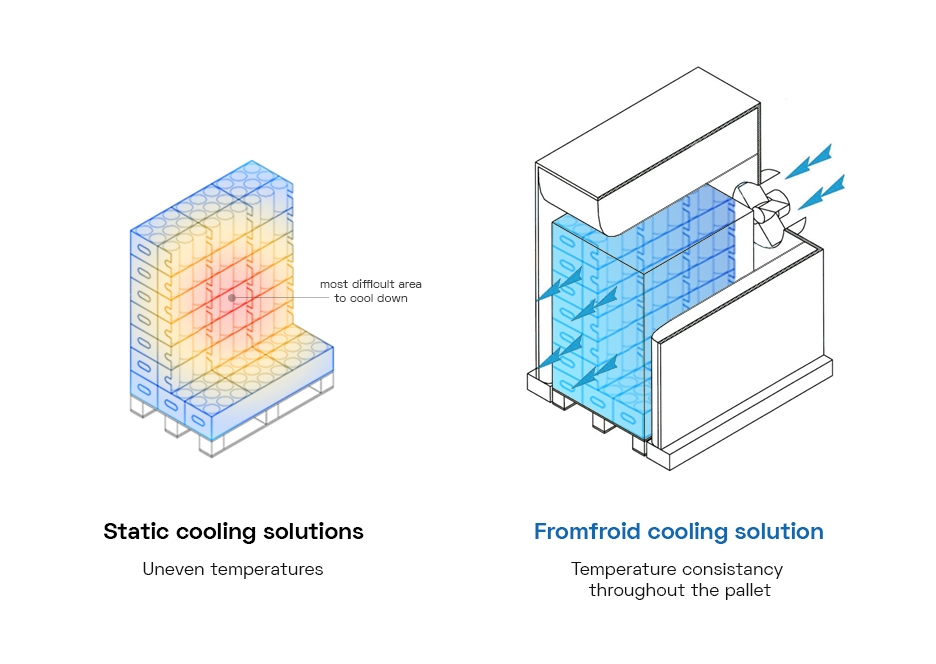

Unlike static or stirred cooling, which is inefficient and deteriorates food quality, we utilize an elevated & dynamic ventilated cooling system that guarantees highly controlled cooling while maintaining the features of the elements such as texture and taste.

We provide three different types of quick cooling options :

- Pallet cooling cells - available in different sizes

- In-line production cooling tunnels

- Single-product rapid cooling tunnels

With our airflow management equipment in cheese factories, the product can be protected from potential contamination while assuring the best quality with regulated shrinkage owing to in-built cell air conditioners.

In comparison to competing solutions, our latest innovation in

high-performance tunnels and cooling cells for yogurt pallets has empowered our customers to cool their complete production output in a uniform and timely manner while consuming less energy.

FROMFROID has developed unique technical expertise that ensures perfect control of your environment and air quality thanks to its 50 years of experience in airflow management and pre-packaging cooling.

FROMFROID has created unique drying procedures adaptable to a wide range of products as an air conditioning expert with experience in the foodservice industry.

We have the right, effective, and energy-saving solution for drying chambers for sweets, drying ovens for fruits and vegetables, or drying and aging rooms for meat processing.

FROMFROID is trusted by all of the world's biggest food manufacturers to keep their pallets of food items fresh & cool (yogurt, cheese, fruit, vegetables, etc.).

We deliver worldwide

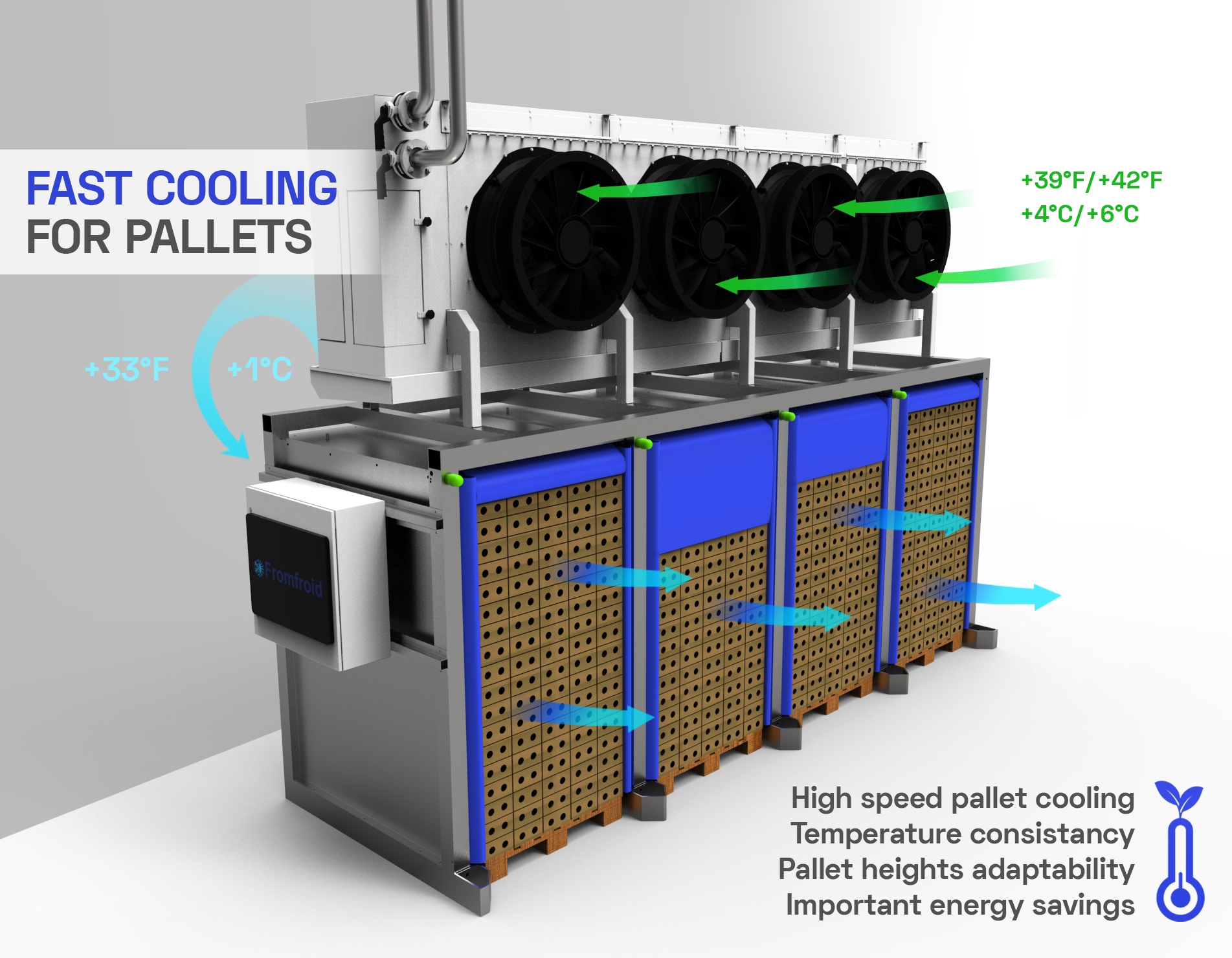

Fast cooling cells for pallets

Speed, flexibility, durability and energy reduction

FROMFROID has created a one-of-a-kind market product: a high-performance quick cooling cell for pallets. FROMFROID engineers designed these patented cells to meet your need s:

- High adaptability: supports a variety of pallet heights.

- High energy efficiency: significant energy savings when compared to alternative technologies.

- Improved ultimate temperature homogeneity for superior product control

- Installable on numerous levels to maximize storage space

Fast cooling tunnels for pallets

Speed, volume, reliability and energy reduction

The High-Performance Cooling Tunnel for Pallets is Fromfroid's second revolutionary solution. Our engineers designed this innovative tunnel to match your requirements :

- Pallet heights are highly variable

- In comparison to competing technologies, high energy efficiency

- High production speeds and the simultaneous processing of many goods

- Designed for completely automated processes in plants

- Cooling durations are shorter, installations are smaller, and efficiency and productivity are higher.

- Better uniformity of final temperatures throughout the product to ensure that textures and flavors are preserved.

Fast cooling tunnels for single products

FROMFROID offers in-line cooling solutions for single products such as cookies, compotes, fresh pasta, or any other food product.

These solutions include conveyor elements (belt or modular mesh conveyors), integrating blowing and cooling devices, while guaranteeing the highest levels of hygiene, accessibility and cleanability.

Always looking for the best equipment in terms of quality and reliability, FROMFROID uses SG2C conveyor technology, which is internationally recognized for its qualities in terms of precision and cleanability.

Yoghurts

Temperature control (incubation and cooling) is critical in the yogurt manufacturing process, since it affects different parameters such as taste, odor, color, feel, pH, and shelf life significantly.

Despite the fact that these procedures are essential for product quality, they have been lacking in efficient and optimized systems for a long time.

FROMFROID has developed exceptional & reliable systems that allow you to standardize your processes.

Incubation rooms / ovens

FROMFROID has developed distinctive and trusted solutions for establishing and regulating the temperature in your ovens in order to achieve the best quality and consistency in your production.

Incubation is an important aspect of the yogurt-making process, and having it under control provides higher quality yogurt with stable organoleptic properties.

Air homogeneity at all points in the room is not guaranteed by traditional techniques. As a result, the pH evolution differs between each pot and each pallet, resulting in varying quality.

To address these issues, FROMFROID has created new solutions that ensure a continuous pH change in each jar and, as a result, full control of the incubation process.

Rapid cooling cells for pallets

The most versatile and flexible equipment for swiftly cooling your yogurts and creams is the rapid cooling cells for pallets. The cells are ideal for factories with many product formats/jar sizes as they are equipped with an internationally patented technology and are adaptable to all forms of production.

The cells are easily automated and can be deployed in cold rooms with shuttles or automatic stackers.

Fast cooling tunnels for pallets

Fast cooling tunnels for pallets are designed for enterprises with a limited number of formats but high production volumes. The quick cooling tunnels, which are equipped with the proprietary FROMFROID technology, are the most energy-efficient in the market for yogurt manufacturing, in terms of usage, cooling speed, and uniformity.

Cheese factory

FROMFROID will assist you throughout your project, from managing your plant's airflow to sourcing and installing air conditioners at your various spots, to ensure the highest product quality and minimize your energy consumption.

Airflow control and ultra-cleanliness.

To keep the risk of contamination in your plant at a minimum, you must first identify the contaminating substances before properly directing and treating them.

FROMFROID has been dedicated to offering the best solutions to combat contamination concerns in agri-food facilities, notably dairy, for nearly 50 years.

FROMFROID is active in your project throughout to ensure that you have the right equipment to attain, the best reliability, quality, and hygiene.

Stainless steel air conditioners

Stainless steel air conditioners from FROMFROID are essential for air conditioning in cheese factories because they provide optimal and ultra-precise temperature, humidity, and gas concentration management in the various production and aging rooms while also maintaining absolute hygiene via CIP.

FROMFROID is involved throughout your project to provide you with the best equipment to guarantee reliability, quality and hygiene.

Within your production unit, we are involved in

- the production room

- the draining room

- the drying room

- the refining room

- the storage rooms

Since the cheese industry blends technology and history, FROMFROID is dedicated to providing you with high-performance equipment that meets your product's quality requirements.

Biscuits / cookies

FROMFROID is a food industry specialist in rapid cooling and industrial air conditioning solutions. Through its fast cooling tunnels, the company has gained expertise and competence in the cookie/biscuit industry.

After baking, cooling is the next crucial stage in the cookie and bakery business.

Owing to that, for both new projects and line optimization, FROMFROID manufactures and delivers rapid cooling tunnels that exceed the most demanding criteria (cooling speed, hygiene, and ease of maintenance) while seamlessly integrating into your manufacturing lines.

Do you want to learn more? We can determine which option is ideal for you, free of charge !